Summary

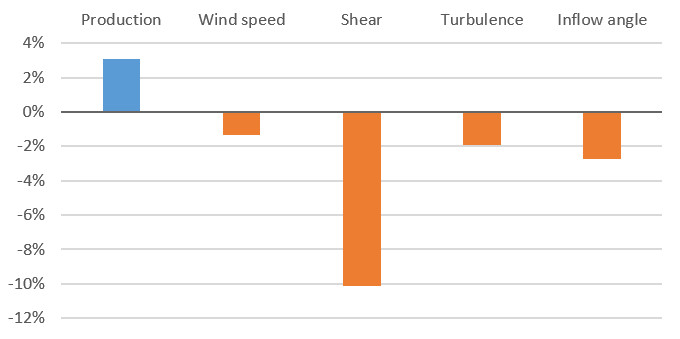

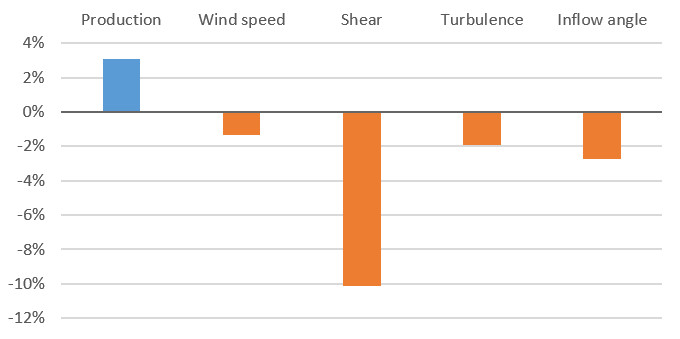

Changes in production and wind load parameters after Meventus performed wind farm layout optimization.

Changes in production and wind load parameters after Meventus performed wind farm layout optimization.