Wind Farm Performance Improvement

Use latest Technology to improve Performance and save Costs!

Meventus applies a set of proven and new methodologies to both improve performance and reduce long term maintenance costs for your wind farm

Park Performance Analysis

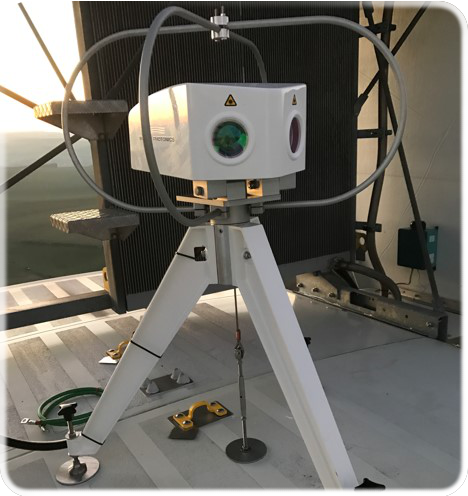

Ground or Nacelle Lidar Measurements

Improvement Strategy

Dynamic Yaw & Pitch Control

Wind Farm Performance Improvement

Improving a wind farm’s performance begins with assessing the current operation, as it is important to understand what is occurring in the park, and what any potential problems are before developing a strategy to improve performance. Every park is different, so simply implementing a post-construction product that improved a similar park may not produce the desired results.

Our preferred approach is to start with a Basic Data Analysis on the available park data (SCADA and any wind measurements). One can generally derive a good understanding of the park’s performance using this data, including identifying problem turbines.

Should the performance assessment confirm there is underperformance or problematic turbines, an improvement strategy will be implemented based on the specific needs. Some examples of improvement measures include Ground Lidar Measurements to create a reference data set and further understand the site conditions and a Nacelle Lidar Campaign on selected turbines to perform various improvement activities such as yaw angle alignment, Nacelle Transfer Function (NTF) adjustment or static sector management as applicable depending on the results from the root cause analysis.

Meventus’ cooperation with both lidar providers and control system developers enables us to implement Dynamic Yaw & Pitch Control as a retrofit solution for the most common turbine models. This permanent switch to a pro-active control mechanism through upstream lidar input compared to a reactive anemometer input from behind the rotor not only allows for smart AEP improvements, but also for significant fatigue load reductions and eventual life cycle maintenance cost reductions.

To demonstrate our confidence in our Wind Farm Performance Improvement capabilities and to minimize your financial risk with our engagement,

Meventus offers this support on a success fee basis,

where our fees will consist of a relatively small, fixed down payment and a certain share of the realized savings over the duration of the campaign.

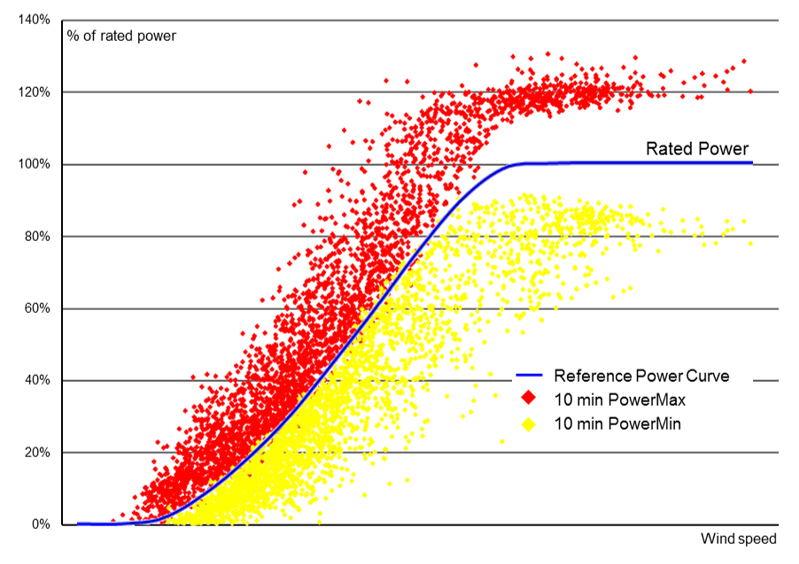

- Blade pitching is a reactive action to a wind speed increase, thus delayed, and the power level can overshoot the rated level (red dots)

- Once the blades have been pitched to regulate the maximum power and a reduction in wind speed occurs, the power will drop to a level that is below the production potential of the turbine (yellow dots) resulting in an energy loss before the blades are pitched to the best angle

- Proactive pitching with a nacelle lidar can reduce losses and fatigue loads

Become an Active Owner with Meventus – Your Partner in Wind!

Would you like to work with us?

If you have an upcoming project in wind and you think we can help you,

please feel free to contact us, we’ll get back to you as soon as possible.