Layout Optimization

Wind and Site Analysis

Summary of results

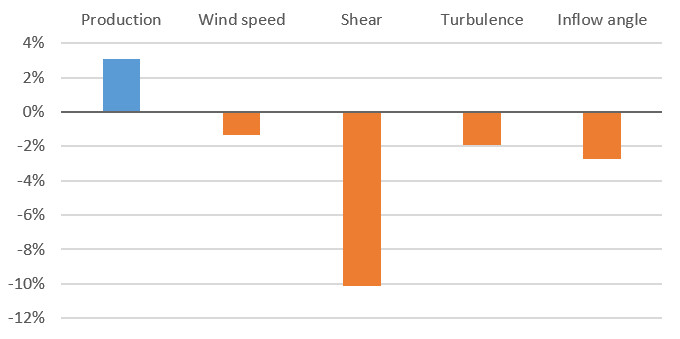

Changes in production and wind load parameters after Meventus performed wind farm layout optimization

Situation and objective

- A first tier wind turbine manufacturer (OEM) was identified as preferred supplier during a WTG procurement process for a Norwegian wind project under development (>100 MW)

- The OEM provided an optimized layout for the wind farm, but failed to comply with layout requirements:

- Project specific exclusions areas

- Noise emission levels

- Road access deemed impossible by road engineer

Approach

- Using our internally developed methods and tools, Meventus provided an alternative layout for the wind project

- The objective was to increase wind farm production while keeping infrastructure costs to a minimum

- The work was done in close collaboration with road engineers to ensure viability of layout

- Optimization was performed to consider road viability as well as noise and shadow flicker, ice throw risk and other permit requirements.

Results and benefits

- Meventus proposed a layout that gave:

- 3% increase in expected Annual Energy Production

- Reduction in all wind load parameters, providing reduced mechanical loading and lower OPEX

- The layout was approved by the OEM’s load calculations as well as governmental approval

- No changes in viability and cost for infrastructure